This article is about Burner Management System (BMS).

What is a Burner management system (BMS)

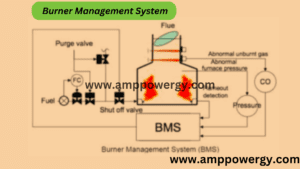

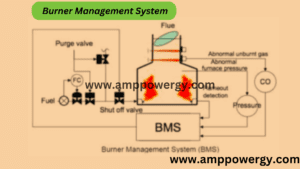

In the production of oil and gas the industries use different types of fire heaters. Opening a gas or oil burning heater can produce safety risks. To take control of these risks industries install a burner management system to the processes of heaters.

The burning management system is a hazard control system which is used in industries for the safe starting, operation and shutdown of heaters. It is also used to minimize the fuel cost, maintenance and to create a safe environment for the worker who works near to the heater. It is to prevent the heater from exploding in the upset condition.

BMS is used in oil and gas, power generation, chemical and so many others. The industries which use the burner, boiler and furnaces then BMS will be install there. Other equipment which uses flame, they also use BMS system. BMS detects flames by flame detector. It is used to manage ignitor, burner and actuator. To ensure the removal of flue gases before fuel injection the BMS provides purge cycle time to the furnace.

Note:

what is a Flame detector: it is a sensor which is designed to sense the presence of flame or fires and response. it is used in different industries like oil, gas, chemical and power generation industries. There are different types of flame detector which include optical flame detector, infrared flame detector, ultraviolet, pyroelectric dual flame detector.

what is an Ignitor: it is a device used to ignite fuel or fires. It is also called a lighter.

what is an Actuator: itis a control component which produces force, torque and displacement when electrical or hydraulic input is applied to it. It moves a system by opening a valve.

Burner management system is two types.

- Manual burner management system

- Automatic burner management system

What is Manual Burner Management System

Manual burner management system is the BMS which is controlled manually that is men will be need for controlling the manual BMS. It can put an operator at risk during start up the ignitor because in manual BMS the ignitor will be started up manually. And the pilot light will also be ignited manually.in these BMS the pilot light is used to ignite the main burner.

What is Automatic Burner Management System

Automatic burner management system is a BMS which is fully automatic, and it does not need manual operation. In a heated vessel the temperature is controlled and monitored manually through a sensor. There is a safety control system in automatic BMS which controls the safe startup and shutdown prosses. This Burner management system can monitor flames with the help of flame detector, it can manage igniters, burners and actuators.

Furnace explosion and implosion

Another major function of BMS is boiler furnace protection against explosion and implosion. Under explosion and implosion, the structure of the furnace can get damage. BMS trip the boiler and cut the fuel supply on high and low furnace pressure due to this the furnace gets damage from inside because of successive blast and disturbance inside the furnace.

Importance of NFPA 85 Code

NFPA 85 takes part in safe operation and is used to prevent explosion and implosion in the boilers.

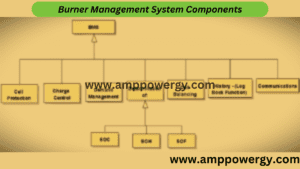

Important Components of Burner Management System

| components | Purpose of the components |

| Burner | In burner fuel, oil or gas is mixed with air and produce heat. Large heaters have multiple burners where the combustion occur. |

| Controller | To control the fuel valve and ignitor of the burner the microcontroller is used for it. |

| Flame detector | It is a sensor which works to sense the presence and absence of the flame and gives signal to the controller. |

| Ignitor | It is installed to give energy to light the main power. |

| Valves | Valves are used to shut off the flow of oil or gas in the fuel system. |

Function of the burner management system

The main purpose of the burning management system is to detect the flame and control the processes. And to ensure the shutdown processes.

Other processes include

- When the combustion chamber purge is not completed it prevents the equipment from starting and firing.

- When the condition is not safe it does not allow the equipment to start.

- During starting and shutdown it controls the sequence of the components.

- It controls the quantity of fuel to the heater.

- It is also providing the feedback about components condition to the operator.

Note:

what is a combustion chamber: combustion chamber is a place where combustion takes place such as a place over a piston. It is a closed space in which fuel and oxidant burn. It is a part of an internal combustion engine where air and fuel are mixed to generate electricity. It is responsible for force, torque and displacement.

Benefits of using a burner management system

It increases the performance of an overall plant and controls the amenability of the plant.

- Safety: using BMS can help to reduce the chances of accident and to increase safety for the workers

- ECO friendly: it also reduces the greenhouse gas emissions to the environment.

- Reduced cost: the use of BMS can also help to reduce the expenses, that is it reduces involvement and shutdown time and can quickly recover from the upset condition. It needs less maintenance.

- Improve reporting capability: it helps to improve the operation because it has an alarm system and can send help messages to the operator.

Important function of the BMS

- Stop startup in unsafe condition.

- It is used to detect unsafe operation condition.

- Shutdown interlock

- Protection against unsafe condition

Whenever the sensor detects an unsafe condition, it gives a signal to the actuator. Actuators stop the flow of fuel to the burner to hold back the flame.

To method is used for BMS implementation separated and integrated method.

The best method of BMS implementation is separated method. In this method the safety instrumented system (SIS) and basic control system (BPCS) are installed in two separate equipment. The workstation and SCADA software are also separated. Both systems communicate with each other by BUS and common communication protocol.

In integration method the SIS and BPCS logic solver and workstation is in common equipment.

Function of Burner Management System

- Prevent firing before furnace purge completed.

- Prevent startup before interlock is completed.

- It monitors and controls the component during start up and shutdown.

- Provide feedback to the operator about the component condition.

- Provide automatic supervision.

- When unaccepted firing occurs provide feedback to the master fuel trip (MFT).

- Start MFT in unfavorable condition.

Types of the Burner Management System

There are two types of BMS.

Integrated system

Integrated building management system (iBMS) is a system which allows centralized management and control of all buildings. It also controls its environment such as parking spaces, access etc. For the entire building a single iBMS is enough. Air conditioning, security, air quality, supplies, power system, fire detection and parking spaces can be controlled on iBMS.

Advantages of Burner Management System

- Decreases intervention and shutdown time.

- Recover Easly from the upset condition.

- Reduce installation cost.

- Easy and less Maintenace is required.

- Improve accessibility.

- No need of more operation persons

Disadvantages Burner Management System

- It is less flexible.

- Separated system is easier to operate, while iBMS is hard to operate.

What happens if you don’t use a BMS?

If you don’t use the BMS then the chances of fire and accident will increase. The burning gas will flow if the Pilet goes out, while there will be no temperature control system, the main burner gas will go out until you shutdown it manually. This can produce a critical situation and can cause damage and it is very dangerous and expensive.

frequently asked questions about Burner Management System (BMS)

Q1: what is a burner management system (BMS)?

Ans: it is a safety system which is used to make sure safe start up, operation and shutdown processes. It is used in oil, gas, power generation and chemical industries for safety.

Q2: How does a BMS work?

Ans: There is a safety control system in automatic BMS which controls the safe startup and shutdown prosses. This Burner management system can monitor flames with the help of flame detector, it can manage igniters, burners and actuators.

Q3: What are the components of the burner management system?

Ans: the components of burner management system include:

- Flame sensor

- Control panels

- Fuel train

- Safety shut up valve

Q4: What is the difference between automatic and manual burner management systems?

Ans the automatic BMS is the system which is fully automatic and does not need manual operation and the manual BMS is the system which is operated through manually that is the igniter will operate manually.

Q5: What are the benefits of BMS?

Ans: The benefits of BMS include:

- Safe start up of burner

- Safe operation of burner

- Safe shut down of burner

- Saving fuel costs

- Minimize maintenance of burner

- Create safe environment for workers

- Improve up time

9 thoughts on “Burner management system (BMS), Functions, Types, Advantage and Disadvantage”