Linear Potentiometer?

Definition:

Linear potentiometer or linear pot is a type of potentiometer which is like a variable resistor. Linear potentiometer is used to translate or convert the linear motion into the electrical signals, linear motion means Stright movement on the line. It specially behaves like a potion sensor for one direction, up and down or left and right.

Key components of linear potentiometer are:

- Three terminals

- Resistance variation

- Voltage division

Three terminals: it has three terminals; two terminals are fixed, and the other one is movable which slides along it, and this movable terminal is called wiper.

Resistance variation: the resistance between the fixed and the movable end changes when the wiper moves.

Voltage division: the wiper behaves like a variable tap when the constant voltage is applied to it and determines output voltage with the help of its position and this voltage is proportional to the viper location.

Types of Linear Potentiometer

Linear potentiometers, also known as slide potentiometers or slider potentiometers, are variable resistors that change resistance along a linear path. They are commonly used in a variety of electronic devices for control and measurement purposes. Here are some types of linear potentiometers:

- Carbon Track Linear Potentiometer: These potentiometers use a resistive carbon track along which a wiper moves linearly, changing the resistance as it moves. They are commonly used in audio equipment, such as mixing consoles and amplifiers.

- Wire wound Linear Potentiometer: In wire wound potentiometers, a resistive wire is wound around a core, and a wiper moves along this wire to change the resistance. They offer high precision and are often used in industrial applications where accuracy is critical.

- Cermet Linear Potentiometer: Cermet (ceramic-metal) potentiometers use a resistive layer made of a ceramic-metal composite material. They provide good stability and durability, making them suitable for various applications, including industrial controls and automotive systems.

- Hybrid Linear Potentiometer: Hybrid potentiometers combine different materials and technologies to achieve specific performance characteristics. For example, a hybrid potentiometer may use a combination of carbon and conductive plastic for improved linearity and durability.

- Fader Potentiometer: Fader potentiometers are specialized linear potentiometers designed for audio mixing consoles and DJ equipment. They have a long, narrow slider that allows for precise control of audio levels across multiple channels.

- Motorized Linear Potentiometer: Motorized potentiometers feature a built-in motor that automatically adjusts the wiper position based on external control signals. They are commonly used in automated systems and audio/video equipment that require remote control functionality.

- Optical Linear Potentiometer: Optical potentiometers use light-based technology to measure the position of the wiper. They offer high precision, low wear, and long-term reliability, making them suitable for applications where accuracy is paramount.

- Membrane Potentiometer: Membrane potentiometers consist of a flexible membrane with a resistive track printed on its surface. When pressure is applied, the membrane deforms, causing the wiper to move along the resistive track and change the resistance.

Working Principle of Linear Potentiometer

The working principle of a linear potentiometer is based on the variation of resistance along a linear path. Here’s how it typically works:

- Construction: A linear potentiometer consists of a resistive element, usually in the form of a track, strip, or wire, along which a movable contact, known as a wiper or slider, can slide linearly. The resistive element is often made of materials like carbon, wire wound around a core, or cermet (ceramic-metal composite).

- Application of Voltage: A voltage is applied across the entire length of the resistive element. This voltage creates a potential difference across the element, resulting in a linear variation of voltage along its length.

- Variable Resistance: As the wiper moves along the resistive element, it makes contact with different points on the track. The resistance between the wiper and one end of the track varies depending on the wiper’s position. When the wiper is at one extreme, the resistance is at its maximum, and when it’s at the other extreme, the resistance is at its minimum. The resistance changes linearly with the position of the wiper.

- Output Signal: The output signal from a linear potentiometer is typically the voltage or current that corresponds to the position of the wiper along the resistive track. By measuring this output signal, one can determine the position of the wiper and, consequently, the position along the linear path.

- Usage: Linear potentiometers are commonly used in various applications where linear position sensing or control is required. They are found in audio equipment for volume control, in industrial machinery for position feedback, in automotive systems for throttle position sensing, and in many other devices where linear motion needs to be converted into an electrical signal.

Overall, the working principle of a linear potentiometer involves the variation of resistance along a linear path, with the position of a movable wiper determining the amount of resistance in the circuit and thus generating an electrical signal proportional to its position.

Application of Linear Potentiometer

Linear potentiometers find applications in various industries and fields due to their ability to provide linear position sensing and control. Here are some common applications:

- Audio Equipment: Linear potentiometers are widely used in audio equipment for volume control, tone adjustment, and balance control in stereo systems, amplifiers, mixing consoles, and musical instruments.

- Industrial Automation: Linear potentiometers are used for position feedback in industrial automation systems. They provide accurate position sensing in machinery such as linear actuators, hydraulic cylinders, and robotic arms, allowing precise control of motion.

- Automotive Systems: Linear potentiometers are employed in automotive applications for throttle position sensing, pedal position sensing, suspension systems, and gearbox position sensing. They help in controlling engine performance, vehicle dynamics, and transmission systems.

- Medical Devices: Linear potentiometers are used in medical devices for various purposes, including adjusting the height of hospital beds, controlling the position of medical equipment, and monitoring the movement of surgical instruments during procedures.

- Aviation and Aerospace: Linear potentiometers are utilized in aircraft and spacecraft for position sensing in control surfaces, landing gear systems, throttle controls, and flight simulators. They provide critical feedback for flight control systems and cockpit instruments.

- Test and Measurement Equipment: Linear potentiometers are integrated into test and measurement instruments for precise position control and measurement, such as in calibration equipment, material testing machines, and linear displacement sensors.

- Consumer Electronics: Linear potentiometers are found in consumer electronics products like televisions, radios, home theater systems, and gaming consoles for user interface controls, such as adjusting brightness, contrast, and channel selection.

- Environmental Monitoring: Linear potentiometers are used in environmental monitoring systems to measure linear displacement or position changes in sensors for applications such as weather stations, soil moisture monitoring, and water level detection.

- HVAC Systems: Linear potentiometers are employed in heating, ventilation, and air conditioning (HVAC) systems for adjusting damper positions, controlling airflow, and regulating temperature settings in commercial and residential buildings.

- Motion Control Systems: Linear potentiometers are integrated into motion control systems for precise positioning of components in manufacturing equipment, CNC machines, and automated assembly lines.

Construction of Linear Potentiometer

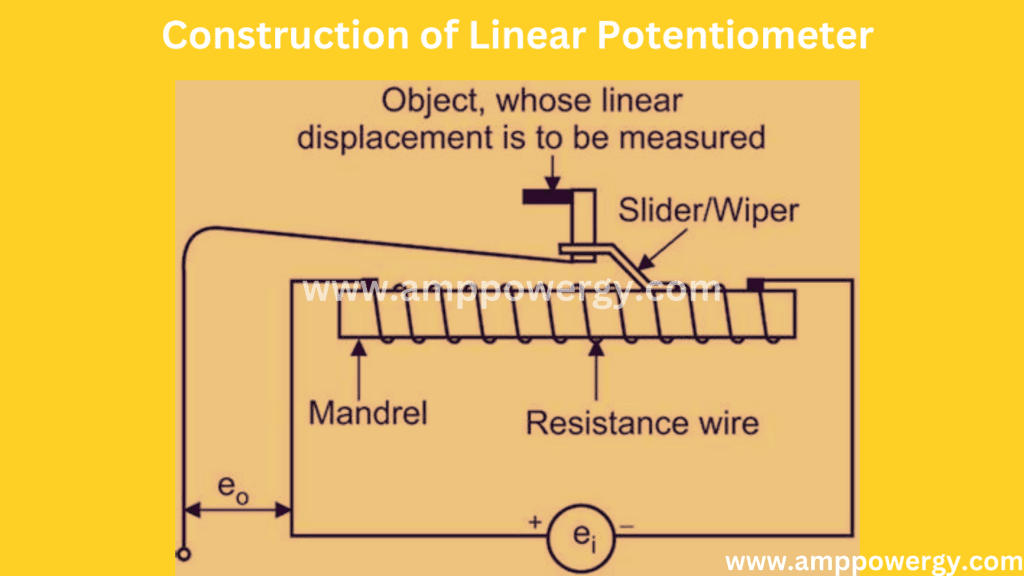

The construction of a linear potentiometer generally involves several key components arranged to facilitate linear motion and resistance variation. Here’s a typical construction:

- Resistive Element: The core of a linear potentiometer is its resistive element, which is usually a long, narrow strip or track made of a resistive material. This material could be carbon, conductive plastic, wire wound around a core, or a cermet (ceramic-metal composite). The resistive element is chosen for its stable resistance characteristics and durability.

- Slider/Wiper: A movable contact, often referred to as a slider or wiper, is attached to the potentiometer’s sliding mechanism. This slider moves along the resistive element in a linear fashion, making electrical contact with the resistive material. The position of the slider along the resistive element determines the output voltage or resistance of the potentiometer.

- Terminals: The resistive element has two fixed terminals, one at each end, to which the input voltage is applied. Additionally, there is a terminal connected to the slider, which serves as the output terminal. The output voltage or resistance of the potentiometer is measured across the slider terminal and one of the fixed terminals.

- Enclosure: Linear potentiometers are typically housed in a protective enclosure to shield the internal components from environmental factors such as dust, moisture, and mechanical damage. The enclosure may be made of plastic, metal, or other suitable materials depending on the application requirements.

- Guidance Mechanism: To ensure smooth and linear motion of the slider along the resistive element, linear potentiometers often incorporate a guidance mechanism. This mechanism may consist of bearings, bushings, or sliding surfaces that reduce friction and wear, thus maintaining the accuracy and reliability of the potentiometer over time.

- Mounting Hardware: Linear potentiometers are designed to be mounted securely in place within a device or system. They may feature mounting holes, brackets, or other hardware to facilitate installation and integration into various applications.

- Sealing: In some applications where environmental protection is crucial, linear potentiometers may include sealing mechanisms such as gaskets or O-rings to prevent moisture or contaminants from entering the enclosure.

Advantages

- Simple Design: Linear potentiometers have a straightforward construction consisting of a resistive track and a sliding contact (wiper), making them easy to understand and use.

- Linear Output: As the name suggests, linear potentiometers provide a linear relationship between the position of the wiper and the output voltage or resistance, which simplifies calibration and control in many applications.

- Cost-Effective: Compared to some other types of position sensors, linear potentiometers are often more cost-effective, especially for applications that do not require extremely high precision.

- Ease of Integration: Linear potentiometers can be easily integrated into existing systems due to their compatibility with standard electrical connections and mounting options.

- Customizable: They can be customized to meet specific application requirements in terms of resistance range, physical dimensions, and mounting configurations.

- Reliable: When properly installed and maintained, linear potentiometers can provide reliable performance over long periods, especially in applications where environmental conditions are controlled.

Disadvantages:

- Limited Lifespan: The sliding contact (wiper) in linear potentiometers can experience wear over time, leading to degradation of performance and eventual failure, especially in high-cycle or high-precision applications.

- Non-Contactless Operation: Unlike some other position sensors like optical encoders or Hall effect sensors, linear potentiometers require physical contact between the wiper and the resistive track, which can result in mechanical wear and potential reliability issues.

- Limited Resolution: Linear potentiometers may have limited resolution compared to certain digital position sensors, which can affect the accuracy and precision of position measurements in applications requiring very fine adjustments.

- Environmental Sensitivity: Linear potentiometers may be susceptible to environmental factors such as dust, moisture, temperature variations, and vibration, which can impact their performance and longevity, especially in harsh operating conditions.

- Electrical Noise: In some cases, linear potentiometers may introduce electrical noise into the system, particularly if the wiper makes poor contact with the resistive track or if the track is contaminated.

- Limited Range: Depending on the specific design and construction, linear potentiometers may have limitations on the maximum length of travel or the range of resistance values they can reliably provide.

Frequently Asked Questions (FAQs)

What is a linear potentiometer?

- A linear potentiometer is a type of variable resistor that changes resistance along a linear path. It typically consists of a resistive element and a movable contact (slider) that moves along the element to vary the resistance.

How does a linear potentiometer work?

- A linear potentiometer works by varying the electrical resistance along its resistive element. As the slider moves along the resistive track, the resistance between the slider and one end of the track changes, allowing the potentiometer to produce an output voltage or resistance proportional to the slider’s position.

What are the applications of linear potentiometers?

- Linear potentiometers find applications in various industries, including audio equipment for volume control, industrial automation for position feedback, automotive systems for throttle position sensing, medical devices for position adjustment, and many others.

What are the different types of linear potentiometers?

- Linear potentiometers can be classified based on their resistive material (carbon, wire wound, cermet, etc.) or specific features (motorized, fader, membrane, etc.). Common types include carbon track, wire wound, cermet, motorized, and fader potentiometers.

How accurate are linear potentiometers?

- The accuracy of a linear potentiometer depends on factors such as its construction, the quality of materials used, and the precision of its manufacturing. Higher-quality potentiometers can offer greater accuracy and repeatability.

What are the advantages of using linear potentiometers?

- Linear potentiometers provide linear position sensing and control, are relatively simple to use, and offer a cost-effective solution for various applications. They also come in a range of sizes and resistance values to suit different requirements.

Can linear potentiometers be used in harsh environments?

- Linear potentiometers can be designed with protective enclosures and sealing mechanisms to withstand harsh environments, including exposure to dust, moisture, and temperature variations. However, the specific level of environmental protection may vary depending on the potentiometer’s design and construction.

How do I select the right linear potentiometer for my application?

- When selecting a linear potentiometer, consider factors such as the required resistance range, linearity, durability, environmental conditions, mounting options, and electrical specifications to ensure compatibility with your application’s requirements.

Are there any maintenance requirements for linear potentiometers?

- Linear potentiometers generally require minimal maintenance. However, periodic cleaning of the resistive element and slider to remove dust and debris can help maintain optimal performance and prolong the potentiometer’s lifespan.

Can linear potentiometers be replaced with other types of position sensors?

- Depending on the specific requirements of the application, linear potentiometers can sometimes be replaced with alternative position sensors such as linear encoders, Hall effect sensors, or LVDTs (Linear Variable Differential Transformers). However, each type of sensor has its own advantages and limitations, so careful consideration is necessary when choosing a replacement.