What are the 3 Stages of Gas Turbine?

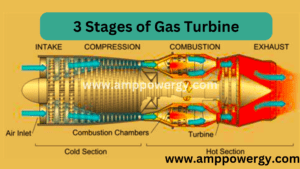

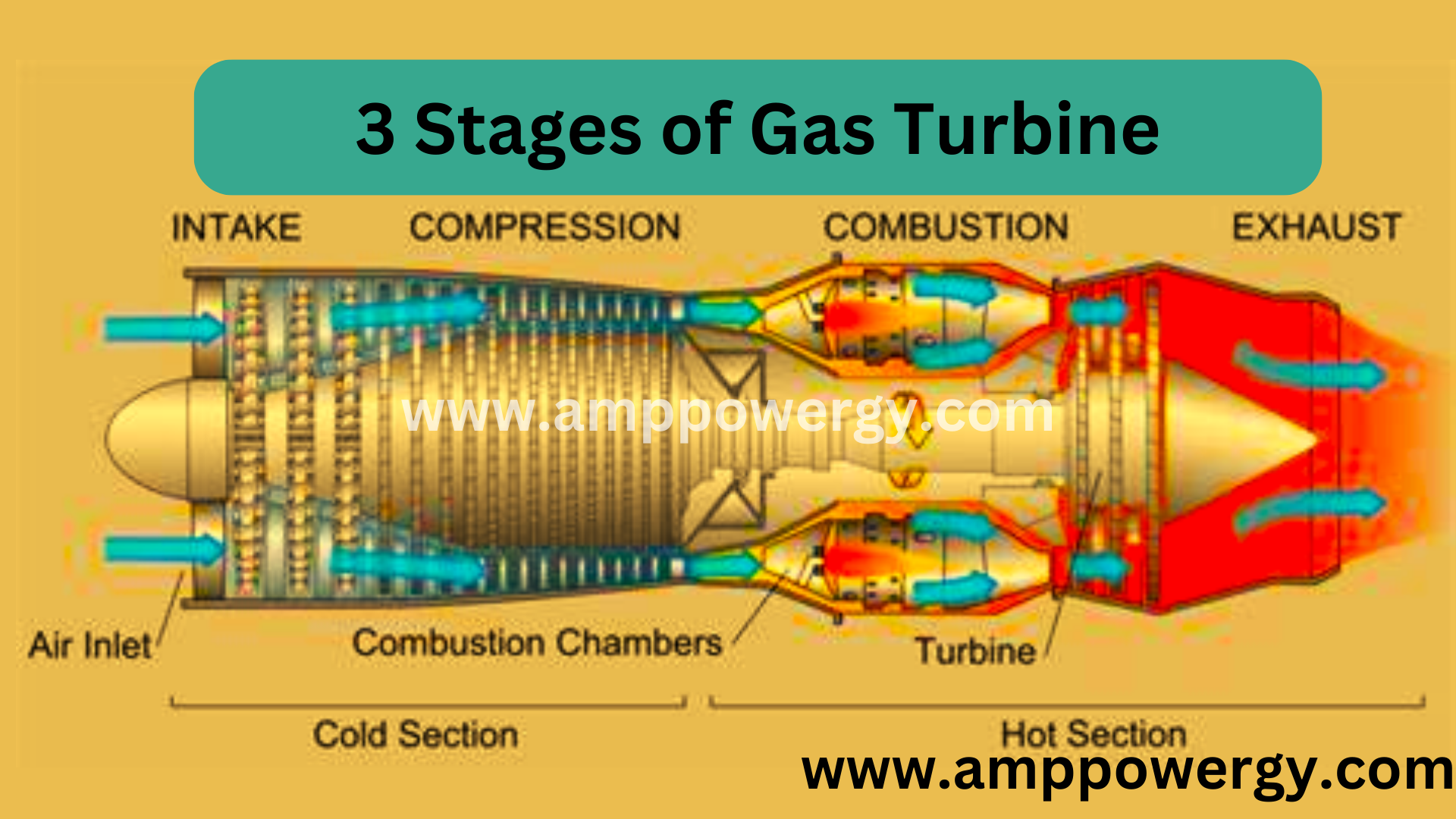

The three main stages of a gas turbine are:

- Intake or Inlet Stage

- Combustion Stage

- Expansion or Turbine Stage

What is Intake or Inlet Stage?

In the intake or inlet stage of a gas turbine, ambient air is drawn into the system to start the power generation process. Here’s a closer look at this stage:

Air Intake: The process begins with the air intake system, which usually consists of ducts and filters designed to ensure the quality and cleanliness of the air entering the turbine. These filters remove debris, dust, and other contaminants from the incoming air to protect turbine components from damage.

Inlet Guide Vanes: Some gas turbine designs incorporate adjustable inlet guide vanes at the entrance to the compressor section. These vanes help control the air flow to the compressor and improve efficiency by adjusting the angle of attack of the incoming air.

Compression: After entering the turbine, the surrounding air enters the compressor section. Here, the air passes through a series of rotating blades, called compressor blades or stages, which compress the air. Each stage of compression increases the pressure and temperature of the air as it approaches the combustion chamber.

Temperature Regulation: During compression, the temperature of the air increases significantly due to the increase in pressure. To prevent overheating and maintain optimal operating conditions, gas turbines often use various cooling techniques, such as bleed air systems or intercoolers, to regulate the temperature of the compressed air.

Overall, the intake or inlet stage of a gas turbine forms the basis of the power generation process and prepares and compresses the surrounding air to mix with the fuel and burn it in the combustion chamber. Efficient operation of this stage is essential to maximize the efficiency and effectiveness of the gas turbine system.

What is Combustion Stage?

The combustion stage of a gas turbine is where compressed air from the intake stage is mixed with fuel and burned to produce high-temperature, high-pressure gases. Here is an overview of this important step:

Combustion Chamber: After compression in the compressor stage, high pressure, high temperature air enters the combustion chamber. This chamber is designed to mix the compressed air with the fuel and provide the necessary conditions for combustion.

Fuel Injection: Fuel, usually in the form of liquid or gaseous hydrocarbons such as natural gas, diesel, or aviation fuel, is injected into the combustion chamber. The injection quantity is carefully controlled to maintain the desired fuel-to-air ratio, ensuring efficient combustion and optimum performance.

Ignition: Once the fuel is introduced into the combustion chamber and mixed with compressed air, it is ignited to start the combustion process. Ignition can be achieved using a variety of methods, such as spark plugs or continuous combustion in some designs. The fuel-air mixture burns rapidly, releasing a significant amount of thermal energy.

Flame Stability: The combustion process creates a flame front those spreads through the fuel and air mixture in the combustion chamber. Various design features, such as flame holders or stabilizers, help maintain stable combustion by preventing flame bursts or instability, ensuring consistent gas turbine performance.

Heat production: As the fuel and air mixture burns, it releases heat energy, which increases the temperature and pressure of the gases inside the combustion chamber. These hot, high-pressure gases are then directed to the turbine section of a gas turbine to extract mechanical energy.

The combustion stage is important for converting the chemical energy stored in the fuel into thermal energy, which is then converted into mechanical energy by the turbine. Efficient and stable combustion is essential to maximize the efficiency, effectiveness and reliability of a gas turbine system.

What is Expansion Stage?

The expansion stage of a gas turbine is where the high-temperature, high-pressure gases produced in the combustion chamber are used to generate mechanical energy. here are the steps:

Turbine Section: After the combustion process, the hot gases flow into the turbine section of the gas turbine. A turbine section usually consists of multiple stages of stationary and rotating blades arranged in a series.

Expansion: As the hot gases pass through the turbine stages, they expand and lose pressure while transferring energy to the turbine blades. This expansion causes the turbine blades to rotate like a windmill or water turbine, converting the thermal energy of the gases into mechanical energy in the form of rotational motion.

Rotary Motion: The rotating turbine shaft is connected to the compressor section of the gas turbine. As the turbine blades rotate, they drive the compressor, which continues to draw and compress air for the combustion process. In some gas turbine applications, such as power generation or aircraft propulsion, the turbine shaft may also be connected to a generator or propeller to produce power or thrust, respectively.

Exhaust: After passing through the turbine stages, the now expanded and reduced pressure gases exit the turbine section and are released into the atmosphere through the exhaust system. These exhaust gases still contain some residual energy but are considerably cooler and less pressurized than they were before entering the turbine.

The expansion stage of a gas turbine is where the majority of energy conversion occurs, as the high-temperature, high-pressure gases are efficiently converted into useful mechanical work. Optimizing turbine section design and operation is critical to maximizing gas turbine system performance, efficiency, and reliability.

Frequently asked questions (FAQs)

See Also:

difference between Francis and Kaplan turbine

what is turbine and its function?

What is the purpose of the intake stage in a gas turbine?

The intake stage is responsible for drawing ambient air into the system, which is then compressed and prepared for combustion. This ensures a constant flow of air to drive the turbine and supports efficient combustion in the subsequent stages.

How does the combustion stage work in a gas turbine?

The combustion stage involves mixing compressed air with fuel and burning the mixture to produce high-temperature, high-pressure gases. These gases contain the energy released during combustion, which is used to drive the turbine and generate mechanical power.

What role does the expansion stage play in a gas turbine?

The expansion stage uses the energy of the hot, high-pressure gases produced in the combustion stage to drive the turbine blades. As the gases expand through the turbine, they transfer their energy to the blades, causing them to rotate and creating mechanical work.

How are the three stages of a gas turbine interconnected?

The three stages of a gas turbine work together in a continuous cycle. The intake stage supplies compressed air to the combustion stage, where it is mixed with fuel and burned. The resulting high-pressure gases pass through the expansion stage, driving the turbine and completing the cycle.

What factors affect the efficiency of each stage in a gas turbine?

A number of factors, including compressor design, fuel-to-air ratio in the combustion chamber, turbine blade material, and exhaust system efficiency, can affect the performance and efficiency of each stage. Optimizing these factors ensures that the gas turbine operates at its peak efficiency.

How is a gas turbine different from other power generation systems?

Gas turbines differ from other power generation systems, such as steam turbines or reciprocating engines, in relying on continuous combustion and the Brayton cycle. They are typically used in applications where high power-to-weight ratios and fast startup times are required, such as aircraft propulsion and packing power plants.

very informative article