What is Force Sensing Resistor?

A force-sensing resistor (FSR) is a type of sensor that detects changes in electrical resistance in response to the application of force or pressure. FSRs are constructed using a material, often a conductive polymer, that changes its resistance upon application of mechanical stress. The sensor usually consists of this conductive material sandwiched between two electrodes. When a force is applied to the resistance surface, the distance between the electrode’s changes, causing a change in resistance.

The relationship between the applied force and the resulting resistance change is usually non-linear, and the FSR may require calibration to accurately measure and interpret the force. These sensors are commonly used in a variety of applications, including human-machine interface, robotics, medical devices, automotive systems, and industrial processes, where force or pressure detection and measurement is necessary.

Application Force Sensing Resistor

Force-sensing resistors (FSRs) find applications in a variety of fields due to their ability to detect and measure force or pressure. Some common applications include:

Human Machine Interface (HMI): FSR is used in devices such as touchpads, touchscreens, and interactive surfaces to detect the level of pressure applied by the user. It is often seen in consumer electronics such as smartphones, tablets, and game controllers.

Medical devices: FSRs are used in medical applications, such as pressure-sensitive foot insoles to monitor weight distribution during motion analysis or rehabilitation exercises. They can also be used in artificial limbs to sense the force applied by the user.

Robotics: FSR is used in robotics to provide feedback about the force applied by robotic arms or grippers. This enables robots to sense touch and adjust their movements, accordingly, making them safer and more versatile in interacting with the environment.

Automotive Industry: In the automotive sector, FSRs can be integrated into car seats to measure the force applied by passengers. This information can be used for advanced airbag deployment systems or to adjust seat features for comfort and safety.

Sports equipment: FSRs are incorporated into sports equipment, such as pressure-sensitive mats to measure the impact force of athletes during training. They are also used in electronic drum kits and musical instruments to detect the force applied by the player.

Industrial Applications: FSRs are used in various industrial processes where power or pressure monitoring is critical. For example, they can be used in assembly lines to ensure proper force is applied during the manufacturing process.

Wearable technology: FSR can be integrated into wearable devices to monitor and record physical interactions. For example, they can be used in smart gloves to detect hand gestures or in a fitness tracker to measure force exerted during various exercises.

Consumer electronics: FSRs are used in certain types of switches and buttons that respond to touch or pressure, providing a more tactile and responsive user experience.

Virtual Reality (VR) and Augmented Reality (AR): FSRs can be incorporated into VR and AR devices to enhance the user experience by providing haptic feedback based on the force applied during interaction. can be improved.

These examples illustrate the versatility of force-sensing resistors in a variety of applications, where their ability to detect and measure force or pressure is valuable to enhance functionality and improve user interaction.

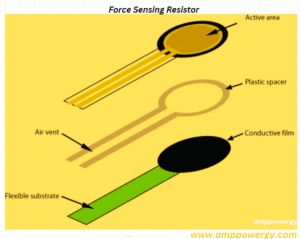

Construction Force Sensing Resistor

Force-sensitive resistors (FSRs) are constructed using materials that exhibit changes in electrical resistance in response to applied force or stress. The basic construction of an FSR typically includes the following components:

Conductive polymer material: The core of the FSR is a conductive polymer material. This material is selected for its ability to change its electrical conductivity when subjected to mechanical stress or deformation. Conductive particles within the polymer move closer together or farther apart, affecting the overall resistivity of the material.

Substrate: Conductive polymer materials are often deposited or coated on a substrate. The substrate provides a stable structure for the sensor and ensures that the conductive elements maintain their position and alignment.

Electrodes: Two electrodes are usually placed on either side of the conductive polymer material. These electrodes can be made of conductive materials such as metal or conductive ink. The electrodes act as terminals to connect the FSR to the external circuit.

Encapsulation: To protect sensitive components from environmental factors and mechanical damage, FSR is often incorporated into a protective layer. This layer can be made of a flexible material to allow the sensor to conform to uneven surfaces.

The working principle of FSR is based on the change in resistance when force is applied. When power is applied to the sensor, the conductive polymer material deforms, causing the distance between the conductive particles to change. This deformation changes the resistance of the material, and an external circuit can measure this change.

It is important to note that the relationship between power and resistance in FSR is often non-linear. Calibration may be necessary to accurately convert resistance changes into meaningful force measurements.

The simplicity and versatility of FSR construction make them suitable for a wide range of applications where force or pressure detection and measurement are required.

Force-sensitive resistors (FSRs) have both advantages and disadvantages, and their suitability for a particular application depends on the specific task requirements. Here are some pros and cons of FSR:

How Force Sensing Resistor Works

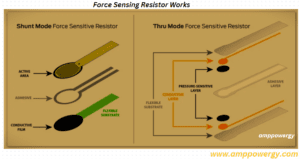

The working principle of a force sensing resistor (FSR) revolves around changes in electrical resistance due to an applied force. Here is a more detailed explanation of how FSR works:

Content Composition:FSRs are made of a polymer matrix containing conductive particles. These particles are usually composed of materials such as carbon or silver.

Arrangement of Conductive Particles:In its resting state (no force applied) the conductive particles within the polymer matrix are distributed in a manner that keeps them apart. This results in relatively high electrical resistance.

Force Application:When an external force is applied to the FSR surface, it compresses the polymer matrix. This compression causes the conductive particles to come closer together.

Change in resistance:The close proximity of conductive particles creates additional paths for electrons to flow through the material. This increased conductivity leads to a decrease in the overall electrical resistance of the FSR.

Voltage measurement:FSRs are often used in voltage distribution circuits. When connected to a voltage source, the output voltage across the FSR is determined by the ratio of the FSR resistance to the total resistance in the circuit. As power is applied, the FSR resistance changes, causing the output voltage to change.

Output signal:The change in electrical resistance is proportional to the power applied to the FSR. This change in resistance can be measured, and the corresponding voltage or current signal can be used as an indication of the applied power.

Calibration: Depending on the specific application, FSRs may require calibration to establish a relationship between the applied power and the resulting electrical output. Calibration ensures accurate and reliable power measurements.

Mathematical Equation for Force Sensing Resistor

The relationship between the force applied to a force sensing resistor (FSR) and its electrical resistance is generally non-linear. FSRs do not follow a simple linear relationship with power, and their response can vary based on the specific design and construction of the sensor.

- R represent the resistance of the FSR under the force

- R0 represent the baselineresistance.

- F represent the applied force

- F0 represent the reference force.

- Β is the exponent

However, a common approach to model the relationship between strength and resistance in FSR is to use an empirical equation. A widely used model is the power law equation:

It is important to note that the values of R0 andβ depends on the specific FSR model and its construction and may need to be determined experimentally through calibration. Furthermore, this equation provides a general representation and may not fully capture the behavior of all FSRs.

When working with FSR in practical applications, experimentation and calibration are important to establish the correct relationship between power and electrical resistance for a specific sensor. Manufacturers often provide data sheets that include calibration information for their FSR products.

Advantages Force Sensing Resistor

Simplicity and cost effectiveness: FSRs are relatively simple to construct, making them cost effective compared to some other force sensing technologies.

Flexible Form Factor: FSRs are often flexible and can conform to irregular surfaces. This flexibility allows for a variety of form factors and applications, including those requiring compatible or wearable sensors.

Lightweight: FSRs are typically lightweight, making them suitable for applications where weight is a concern, such as in wearable devices or lightweight robotic systems.

Low power consumption: FSRs typically have low power consumption, making them suitable for battery-powered devices and applications where energy efficiency is important.

Quick response: FSRs provide quick response to changes in force or pressure, enabling rapid feedback in applications such as touch-sensitive interfaces.

Wide Range of Force Sensing: FSRs are available in different force ranges, allowing versatility in applications with different force requirements.

Easy integration: FSRs are relatively easy to integrate into electronic circuits and systems. They can be easily connected to microcontrollers or other electronic components.

Disadvantages Force Sensing Resistor

Non-linear response: The relationship between applied power and resistance change in FSR is often non-linear. This calibration may be required for accurate power measurements.

Limited accuracy: FSRs cannot provide the same level of accuracy as more sophisticated force sensing technologies, especially in applications that require precise force measurements.

Limited Durability: FSRs may have limited lifespan and durability, especially in applications where they are subject to frequent and heavy use.

Temperature Sensitivity: Changes in temperature can affect the performance of the FSR. Extreme temperature variations can affect sensor accuracy and reliability.

Crosstalk: FSRs can exhibit crosstalk, where power applied to one area of the sensor affects readings in surrounding areas. This can be a limitation in applications that require precise local power measurements.

Sensitivity to Environmental Factors: FSRs may be sensitive to environmental factors such as humidity and may require additional measures to protect them under certain conditions.

Understanding these advantages and disadvantages is important when choosing force sensing technology for a particular application. Depending on the specific requirements, the FSR can be a cost-effective and versatile solution for various force sensing applications.

See Also:

Frequently Asked Questions FAQs

Q: What is force sensitive resistance (FSR)?

Answer: A force-sensitive resistor is a type of sensor that changes its electrical resistance in response to an applied force or pressure.

Q: How does FSR work?

Answer: FSRs work on the principle of a conductive polymer material changing its resistance under mechanical stress. When a force is applied, the distance between the conductive particles in the material changes, which changes the overall resistance.

Q: What are the common applications of FSR?

Answer: FSRs find applications in human-machine interfaces, robotics, medical devices, automotive systems, industrial processes, consumer electronics, and more.

Q: Is the relationship between power and resistance linear in FSR?

Answer: No, this relationship is often non-linear. Calibration may be necessary to accurately interpret resistance changes as meaningful force measurements.

Q: Can FSR be used on uneven surfaces?

Answer: Yes, FSRs are often flexible and can conform to irregular surfaces, making them suitable for a variety of applications.

Q: What are the benefits of using FSR?

Answer: Advantages include simplicity, cost-effectiveness, flexible form factor, lightweight design, low power consumption, quick response, and easy integration into electronic circuits.

Q: Are there any disadvantages to using FSR?

Answer: Disadvantages include non-linear response, limited accuracy compared to more sophisticated sensors, limited durability, temperature sensitivity, susceptibility to environmental factors, and potential crosstalk.

Q: Does the FSR require calibration?

Answer: Yes, calibration is often necessary to ensure accurate power measurements, especially because of the non-linear relationship between power and resistance.

Q: What is the normal age of FSR?

Answer: The lifespan of an FSR may depend on usage and environmental conditions. Heavy and frequent use can lead to premature aging.

Q: Can FSR be used for real-time force feedback?

Answer: Yes, FSRs can be used for real-time force feedback in applications such as touch-sensitive interfaces or robotics to provide immediate response to changes in force.

Q: How are FSRs connected to electronic circuits?

Answer: FSR has two electrodes which act as terminals. They can be easily connected to electronic circuits, often interfaced with microcontrollers or other signal processing devices.

Q: Are FSRs suitable for outdoor applications?

Answer: Depending on the specific model and safety measures, the FSR can be used outdoors. However, factors such as humidity and temperature variations may need to be considered.

1 thought on “What is Force Sensing Resistor?”