What is Coolant Temperature Sensor?

A coolant temperature sensor is a crucial component of a vehicle’s engine management system. It measures the temperature of the engine coolant and sends this information to the engine control unit (ECU) or engine control module (ECM). The ECU uses this data to regulate various engine functions, such as fuel injection timing, ignition timing, and emissions control.

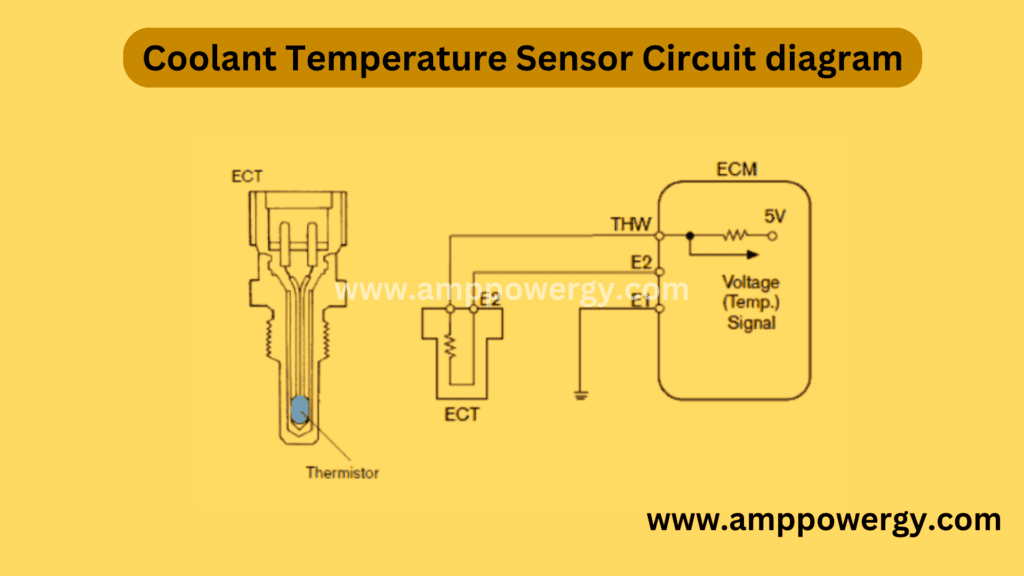

The coolant temperature sensor typically consists of a thermistor—a type of resistor whose resistance varies with temperature—encased in a housing that is immersed in the engine coolant. As the coolant temperature changes, the resistance of the thermistor also changes. This change in resistance is then converted into an electrical signal which the ECU can interpret.

By monitoring the coolant temperature, the ECU can adjust engine parameters to ensure optimal performance, fuel efficiency, and emissions control.

For example, during cold starts, the ECU may enrich the fuel mixture to aid in starting and prevent stalling, while during normal operation, it may adjust fuel and ignition timing for efficient combustion and reduced emissions.

If the coolant temperature sensor fails or malfunctions, it can lead to drivability issues, decreased fuel efficiency, and increased emissions.

Working Principle of Coolant Temperature Sensor

The coolant temperature sensor operates based on the principle of electrical resistance variation with temperature. Here’s how it works:

- Thermistor: The core component of a coolant temperature sensor is a thermistor, which is a type of resistor whose resistance changes with temperature. Typically, thermistors used in coolant temperature sensors have a negative temperature coefficient (NTC), meaning their resistance decreases as temperature increases.

- Thermal Expansion: The sensor is placed in direct contact with the engine coolant. As the coolant temperature rises, it causes the thermistor to heat up. This increase in temperature causes the atoms within the thermistor’s material to vibrate more vigorously, which in turn increases the conductivity of the material and decreases its resistance.

- Resistance Measurement: The engine control unit (ECU) or engine control module (ECM) continuously monitors the resistance of the coolant temperature sensor. It sends a small electrical current through the sensor and measures the voltage drop across it. Since the resistance of the thermistor varies with temperature, the voltage drop across the sensor also changes accordingly.

- Signal Interpretation: The ECU interprets the voltage signal from the coolant temperature sensor and converts it into a corresponding temperature reading. This reading is then used by the ECU to adjust various engine parameters, such as fuel injection timing, ignition timing, and emissions control strategies.

- Feedback Loop: The ECU continuously adjusts engine operation based on the temperature information provided by the coolant temperature sensor. This allows the engine to operate efficiently across a range of operating conditions, from cold starts to normal operating temperatures.

In summary, the coolant temperature sensor works by measuring the electrical resistance of a thermistor immersed in the engine coolant, with the resistance varying in response to changes in coolant temperature. This information is used by the ECU to regulate engine performance and emissions.

Application of Coolant Temperature Sensor

The coolant temperature sensor has several critical applications in a vehicle’s engine management system:

- Engine Performance Optimization: The primary function of the coolant temperature sensor is to provide real-time feedback to the engine control unit (ECU) about the temperature of the engine coolant. This information allows the ECU to optimize engine performance by adjusting parameters such as fuel injection timing, ignition timing, and air-fuel mixture composition.

- Cold Start Enrichment: During cold starts, when the engine is cold, the ECU relies heavily on the coolant temperature sensor to determine the appropriate fuel mixture. A colder engine requires a richer fuel mixture for easy starting and smooth idling. The coolant temperature sensor helps the ECU determine when to enrich the fuel mixture until the engine reaches optimal operating temperature.

- Overheat Protection: If the engine coolant temperature rises above normal operating levels, it can lead to engine damage or failure. The coolant temperature sensor serves as a critical component in the vehicle’s cooling system by providing early warning to the ECU if the coolant temperature exceeds safe limits. The ECU can then trigger protective measures such as activating the cooling fans, reducing engine power, or alerting the driver through warning lights or messages.

- Emissions Control: The coolant temperature sensor plays a crucial role in emissions control systems. It helps the ECU regulate the engine’s air-fuel mixture and ignition timing to ensure efficient combustion and minimize harmful emissions. By maintaining the engine at optimal operating temperature, the coolant temperature sensor contributes to reducing pollutants emitted from the vehicle’s exhaust system.

- Diagnostic Functions: In modern vehicles, the ECU continuously monitors the coolant temperature sensor’s output for abnormalities or malfunctions. If the ECU detects a fault in the coolant temperature sensor or its circuitry, it may trigger a diagnostic trouble code (DTC) and illuminate the check engine light on the instrument panel. This alerts the driver to the need for diagnosis and potential repair of the cooling system.

Overall, the coolant temperature sensor is a critical component for ensuring engine performance, protecting against overheating, controlling emissions, and enabling efficient operation of the vehicle’s cooling system.

Advantages of Coolant Temperature Sensor:

- Optimized Engine Performance: The coolant temperature sensor allows the engine control unit (ECU) to optimize engine performance by adjusting fuel injection timing, ignition timing, and air-fuel mixture composition based on the engine coolant temperature. This optimization leads to improved fuel efficiency, power output, and overall engine responsiveness.

- Overheat Protection: One of the primary advantages of the coolant temperature sensor is its ability to provide early warning to the ECU if the engine coolant temperature rises above safe operating limits. This allows the ECU to trigger protective measures such as activating cooling fans or reducing engine power to prevent engine damage due to overheating.

- Emissions Control: By monitoring the engine coolant temperature, the coolant temperature sensor helps the ECU regulate the engine’s air-fuel mixture and ignition timing, leading to more efficient combustion and reduced emissions of harmful pollutants. This contributes to compliance with emissions regulations and improved environmental performance.

- Cold Start Enrichment: During cold starts, the coolant temperature sensor assists the ECU in determining the appropriate fuel mixture for easy starting and smooth idling. This helps reduce cold-start emissions and ensures reliable engine operation even in cold weather conditions.

- Diagnostic Functionality: The coolant temperature sensor plays a crucial role in vehicle diagnostics by providing feedback to the ECU about the status of the engine cooling system. If the sensor or its circuitry malfunctions, the ECU can detect faults and trigger diagnostic trouble codes (DTCs) to alert the driver to the need for repair.

Disadvantages of Coolant Temperature Sensor:

- Potential for Malfunction: Like any electronic component, coolant temperature sensors are susceptible to failure or malfunction over time due to factors such as wear, contamination, or electrical issues. A malfunctioning coolant temperature sensor can lead to drivability issues, reduced fuel efficiency, and increased emissions.

- Limited Accuracy: While coolant temperature sensors provide valuable feedback to the ECU about the engine coolant temperature, their accuracy may be affected by factors such as sensor location, heat soak, or coolant flow dynamics. Inaccurate temperature readings can result in suboptimal engine performance or false triggering of protective measures.

- Dependency on Cooling System: The coolant temperature sensor relies on the proper functioning of the vehicle’s cooling system to provide accurate temperature readings. If there are issues with the cooling system, such as coolant leaks or a malfunctioning thermostat, the coolant temperature sensor’s performance may be compromised.

Overall, while coolant temperature sensors offer numerous advantages in terms of engine performance optimization, overheating protection, emissions control, and diagnostics, they may also have limitations and potential drawbacks related to reliability, accuracy, and dependency on the cooling system.

Regular maintenance and inspection of the cooling system, including the coolant temperature sensor, are essential to ensure optimal performance and reliability.

Symptoms of Faulty Coolant Temperature Sensor:

A faulty coolant temperature sensor can cause various symptoms, indicating potential issues with the engine or cooling system. Here are some common symptoms to look out for:

- Engine Overheating: If the coolant temperature sensor fails or provides inaccurate readings, the engine control unit (ECU) may not receive the correct temperature information. Thiscan lead to inadequate cooling system operation, resulting in engine overheating. You may notice the temperature gauge on the dashboard indicating higher than normal temperatures or see warning lights related to engine temperature.

- Poor Fuel Economy: A faulty coolant temperature sensor can cause the ECU to inaccurately adjust the air-fuel mixture, leading to either a too rich or too lean fuel mixture. This can result in decreased fuel efficiency and increased fuel consumption, as the engine may not be operating at its optimal fuel-air ratio.

- Hard Starting or Rough Idling: During cold starts, the ECU relies on input from the coolant temperature sensor to determine the appropriate fuel mixture. If the sensor is faulty, it may provide incorrect temperature readings, causing the ECU to deliver an incorrect fuel mixture. This can result in hard starting, prolonged cranking, or rough idling, especially in cold weather conditions.

- Engine Stalling: Inaccurate temperature readings from a faulty coolant temperature sensor can disrupt the engine’s fuel delivery and ignition timing, leading to engine stalling or intermittent loss of power while driving. This can be particularly noticeable when the engine is under load or operating at high temperatures.

- Check Engine Light: A malfunctioning coolant temperature sensor can trigger the check engine light (CEL) to illuminate on the dashboard. The ECU detects discrepancies in sensor readings or circuitry and logs diagnostic trouble codes (DTCs) related to coolant temperature sensor performance. Retrieving these codes with a diagnostic scanner can help pinpoint the issue.

- Erratic Temperature Gauge: A faulty coolant temperature sensor may cause the temperature gauge on the dashboard to behave erratically, jumping between different temperature readings or indicating temperatures that are too high or too low compared to actual conditions.

- Emission Issues: Incorrect coolant temperature readings can affect the engine’s emissions control system, leading to increased emissions of pollutants such as hydrocarbons (HC), carbon monoxide (CO), and nitrogen oxides (NOx). This can result in emissions test failures and environmental harm.

If you experience any of these symptoms, it’s important to have your vehicle inspected by a qualified mechanic to diagnose and address the underlying issue, which may involve testing and potentially replacing the coolant temperature sensor.

How to Fix a Bad Coolant Temperature Sensor:

Fixing a bad coolant temperature sensor typically involves replacing the faulty sensor with a new one. Here’s a step-by-step guide on how to do it:

- Gather Necessary Tools and Materials: Before starting, make sure you have the following tools and materials:

- Replacement coolant temperature sensor (make sure it’s compatible with your vehicle)

- Wrench or socket set

- Coolant (optional, depending on whether coolant needs to be drained)

- Locate the Coolant Temperature Sensor: The coolant temperature sensor is usually located near the thermostat housing, cylinder head, or intake manifold. Refer to your vehicle’s service manual or online resources to find the exact location.

- Prepare the Vehicle: Allow the engine to cool down if it has been running. Park the vehicle on a flat surface and engage the parking brake for safety.

- Disconnect the Battery: As a precaution, disconnect the negative terminal of the battery to prevent any electrical mishaps while working on the sensor.

- Drain Coolant (if necessary): Depending on the location of the coolant temperature sensor, you may need to drain some coolant to access it. Use a drain pan to catch the coolant and dispose of it properly according to local regulations.

- Remove the Old Sensor: Use a wrench or socket set to carefully loosen and remove the old coolant temperature sensor from its mounting location. Be gentle to avoid damaging the surrounding components.

- Install the New Sensor: Carefully thread the new coolant temperature sensor into place by hand. Use a wrench or socket set to tighten it snugly, but avoid over-tightening, as this can damage the sensor or its threads.

- Reconnect Electrical Connector: Reconnect the electrical connector to the new coolant temperature sensor until it clicks into place. Ensure a secure connection to prevent any electrical issues.

- Refill Coolant (if drained): If you drained coolant during the process, refill the cooling system with fresh coolant according to your vehicle manufacturer’s specifications.

- Reconnect Battery: Reconnect the negative terminal of the battery.

- Test Operation: Start the engine and monitor for any leaks or abnormal behavior. Check for proper operation of the temperature gauge on the dashboard and ensure that the engine runs smoothly.

- Clear Error Codes (if necessary): If the check engine light was illuminated due to the faulty coolant temperature sensor, use a diagnostic scanner to clear any stored error codes.

By following these steps, you can effectively replace a bad coolant temperature sensor and restore proper operation to your vehicle’s engine management system. If you’re not comfortable performing this task yourself, it’s advisable to seek assistance from a qualified mechanic.

See Also:

Frequently Asked Questions

Here are some frequently asked questions about coolant temperature sensors:

What does the coolant temperature sensor do?

The coolant temperature sensor measures the temperature of the engine coolant and sends this information to the engine control unit (ECU). The ECU uses this data to adjust various engine functions, such as fuel injection timing, ignition timing, and emissions control.

Where is the coolant temperature sensor located?

The coolant temperature sensor is typically located near the thermostat housing, cylinder head, or intake manifold. Its exact location can vary depending on the vehicle make and model.

How do I know if my coolant temperature sensor is bad?

Common symptoms of a faulty coolant temperature sensor include engine overheating, poor fuel economy, hard starting or rough idling, engine stalling, erratic temperature gauge readings, and illuminated check engine light. Diagnostic trouble codes (DTCs) related to coolant temperature sensor performance may also be logged in the ECU.

Can a faulty coolant temperature sensor cause overheating?

Yes, a faulty coolant temperature sensor can contribute to engine overheating by providing incorrect temperature readings to the ECU. This can lead to inadequate cooling system operation and failure to trigger cooling system components such as the radiator fan or thermostat.

How much does it cost to replace a coolant temperature sensor?

The cost of replacing a coolant temperature sensor can vary depending on factors such as the vehicle make and model, labor costs, and whether the sensor is OEM or aftermarket. On average, the cost of the sensor itself may range from $20 to $100, with additional labor costs if done by a professional mechanic.

Can I drive with a bad coolant temperature sensor?

While it may be possible to drive with a faulty coolant temperature sensor, it’s not recommended. Ignoring symptoms of a bad sensor can lead to engine damage, decreased fuel efficiency, and increased emissions. It’s best to have the sensor replaced as soon as possible to avoid potential problems.

How long does a coolant temperature sensor last?

– The lifespan of a coolant temperature sensor can vary depending on factors such as vehicle usage, operating conditions, and quality of the sensor. In general, coolant temperature sensors can last anywhere from 50,000 to 100,000 miles (about 160934.4 km) or more before needing replacement.

Can I replace the coolant temperature sensor myself?

– Yes, replacing the coolant temperature sensor is a relatively straightforward task that can be done by DIY enthusiasts with basic mechanical skills and the right tools. However, if you’re not comfortable performing the replacement yourself, it’s advisable to seek assistance from a qualified mechanic.

1 thought on “What is Coolant Temperature Sensor?”