This article is about overhead conductor or transmission and distribution conductor

What is Mean by a Conductor

(Overhead Conductors)

An electrical conductor is an object or the type of material which allows the electrical current to flow in one or more directions. Materials which are made from metals are common electrical conductors. Negative charge electron generates electrical current, in some cases the positive charge hole and positive or negative ions generate electricity.

Conductor is a medium for carrying electrical energy from one place to another place. It is very important for overhead and underground transmission and distribution systems. The selection of the conductors depends upon the cost and efficiency. Ideals conductor will have the following properties.

- Its electrical conductivity will be maximum

- Its tensile strength will be high to withstand with the mechanical stress

- It will have least specific gravity

- Its cost will be low

Types of an overhead conductor

Before time copper (Cu) was used for transmission of electrical energy but now it is replaced by aluminum because of the following reason.

- It has low cost then copper.

- Its diameter is high which best for reducing corona effect.

it is an ionization of air because high voltage, which produces light around the conductor which makes sound. Corona also produces the ozone layer therefore it is an undesirable condition.

What is an Advantage of aluminum

- Its conductivity is low

- Its diameter is high which increases surface area to air pressure. It swings in air more than copper.

Because of low tensile strength aluminum is used with other materials such alloys.

What is AAC (All Aluminum Conductor)

(Overhead Conductors)

AAC is made up from one or more strands of hard 1350 aluminum alloy. These AAC (All aluminum conductor) conductors are used in low, medium, and high voltage overhead lines. It is widely used in Urbon areas where high conductivity is required but span does not matter. The corrosion resistance of aluminum is best which made AAC as a choice conductor. Because of low strength its use is limited in transmission lines.

Application AAC (All Aluminum Conductor)

AAC conductor is used for electricity distribution lines which has short span and loading capability is low. It provides the best performance in overhead transmission and distribution systems.

- It has lesser strength and sag is more.

- Because of more sag it is use for lesser span

- It is having better conductivity then ACCR at lower voltage.

- AAC is equal in cost to ACSR.

Advantages AAC (All Aluminum Conductor)

- It is lighter in weight.

- It is good conductivity.

- It is cheap is compared to the others.

- It is resistant to corrosion.

Disadvantage AAC (All Aluminum Conductor)

- It is lower tensile strength due to this it requires more support for the same span.

- Its mechanical strength is lower as compared to the others, so it can damage easily from ice, wind etc.

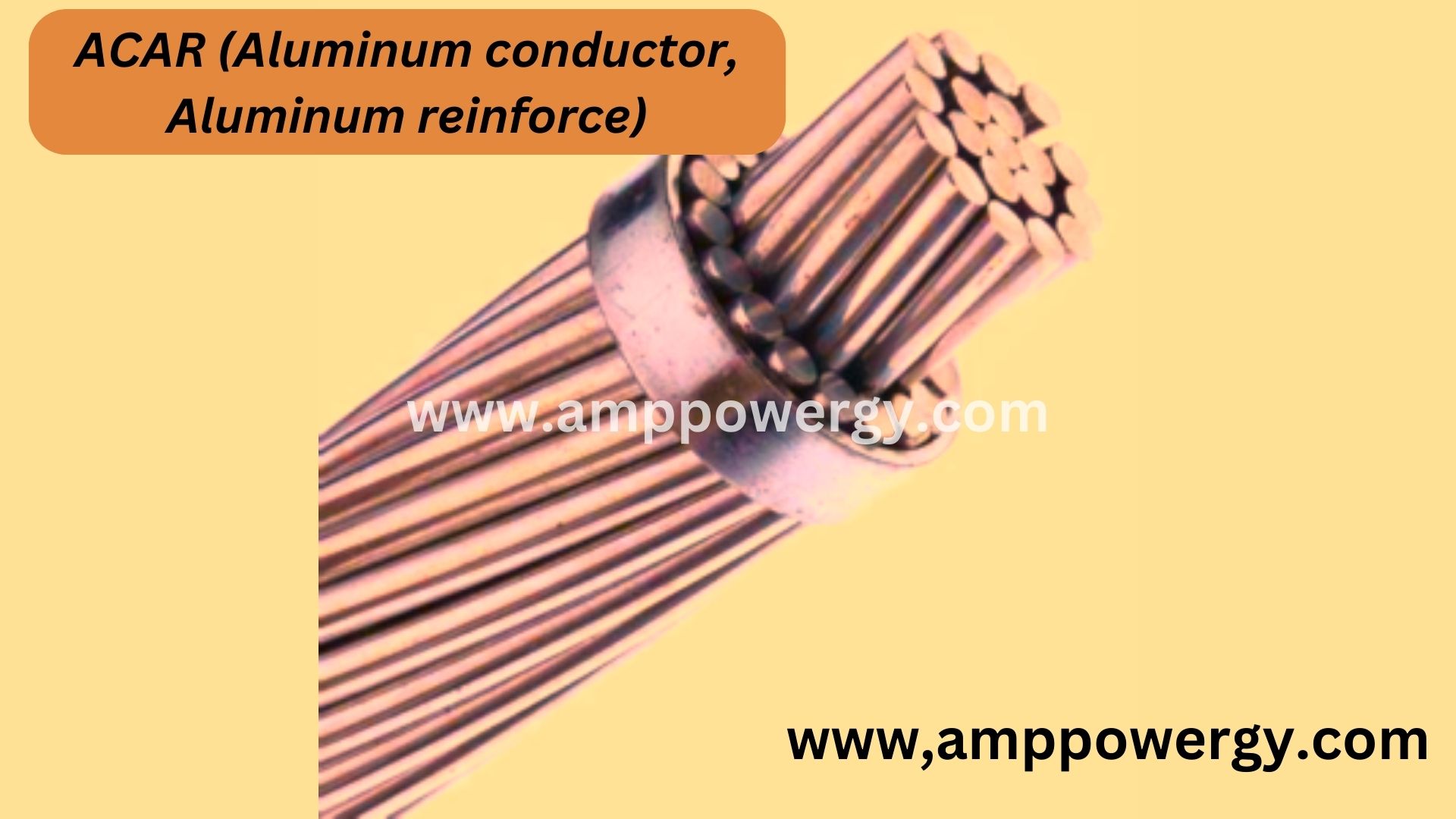

ACAR (Aluminum conductor, Aluminum reinforce)

(Overhead Conductors)

Aluminum conductor, Aluminum reinforces is used to replace the steel core and aluminum wire is used instead. The aluminum wire is the same as common ACSR. The DC resistance of aluminum alloy core is lower than the steel core aluminum. Steel core wire is divided into three classes for corrosion protection which are Class A, Class B, Class C. Additional protection is given by grease on the core.

Application of ACAR (Aluminum conductor, Aluminum reinforce)

Used as a bare overhead transmission cable and use as a primary and secondary distribution cable. It is used for overhead ground wires and for river crossing.

- It has cheaper then AAAC

- It is pro to corrosion.

- It is most expensive.

Advantage ofACAR (Aluminum conductor, Aluminum reinforce)

- It is high strength to weight ratio.

- It can be used for longer spans and requires less support.

- It is more resistant to corrosion.

- It is plain and its transmission capacity is also high.

- Its electrical conductivity is good.

- It is sufficient mechanical strength.

- It is sufficient tensile strength.

Disadvantage of ACAR (Aluminum conductor, Aluminum reinforce)

- Its tensile strength is lower than the ACSR.

- Due to lower tensile strength of ACAR than ACSR so it. requires more support for same span.

- It is more costly than the ACSR.

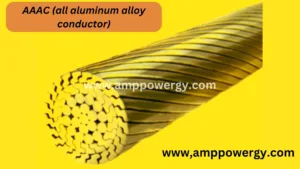

What is AAAC (all aluminum alloy conductor)

(Overhead Conductors)

all aluminum alloy conductor is a concentric lay standard conductor of aluminum alloys. It is available in single and multi-layers. Compared to ACSR its weight is low, best strength and current carrying capacity is high. Low losses and corrosion resistance is high.

Application of AAC (all aluminum alloy conductor)

Used for primary and secondary distribution. AAAC conductor is used for overhead distribution and transmission system, which is near to ocean. And where if there is a problem of corrosion.

It is used in replace of single layer ACSR to reduce the power losses in overhead transmission and distribution system. It can save up to 5-8% of construction cost.

It has high strength, but its conductivity is lower.

- It is same in construction as AAC

- Its light weighted because of no steel use but its strength is equal to ACSR.

- it is expensive because using of alloy

- It is used for longer strength because of stronger tensile than AAC.

- It is used in distribution systems specially for river crossing.

- Its sag is less than AAC.

- It is light weight, so it is used in transmission and sub-transmission system such as mountains where light weight structure is required.

Advantage of AAAC (all aluminum alloy conductor)

- It is lighter in weight.

- Its strength is quite enough.

- Its current carrying capability is good.

- It is lower electrical losses.

- It has superior corrosion resistance.

- It can carry 15 to 20% of extra current.

- Its lifespan is high, approximately 60 years of span life.

- Its surface hardness is higher than the ACSR which is about 80 BHN.

Disadvantage of AAAC (all aluminum alloy conductor)

- Due to the absence of steel its resistance is low.

- Due to the low resistance, it required a large cross-section area to archive the same electrical resistance.

- It is more expensive then ACSR.

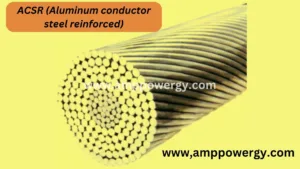

What is an ACSR (Aluminum conductor steel reinforced)

(Overhead Conductors)

ACSR is a stranded conductor with one or more layers of wires of hard drawn 1350-H19 aluminum wire on steel core. The core can be stranded or single wire depending on the size. Steel core wire is available in class A and class b or in Class C galvanization for corrosion protection. Additional protection can be given by grease on the core.

Application ACSR (Aluminum conductor steel reinforced)

It is used in overhead transmission and distribution systems and used in primary and secondary distribution cable. It is used in overhead ground wires and river crossing etc.

- It is used for longer spans and its sag is to keep minimum.

- 7 to 17 strands of steel are surrounded by aluminum strands. The number of strands is shown by x/y/z. Here x is the number of aluminum stands, y is the number of steel strands and z is the diameter of each strand.

- Strand are used to provide flexibility, prevent breakage and skin effect.

- The strands numbers depend on the application. The strands may be 7, 19, 37, 61, 91 or more.

- When the AI and ST strands is separated by filler such as paper then this kind of strand is used in EHV lines and called expanded ACSR

- The expended ASCR has a larger diameter and lower corona losses.

Advantage of ACSR (Aluminum conductor steel reinforced)

- It is high tensile strength.

- It is used for long span with less support.

- This conductor wire has greater diameter.

- Its transmission capacity is high.

- High corona limit can obtain in it.

- Its electrical conductivity is good.

- Its mechanical strength is also good which allow the tower distance to large.

disadvantage of ACSR (Aluminum conductor steel reinforced)

- It requires specialized hardware.

- It required specialized stringing methods as well.

- Its installation and clipping cost are high.

- It required a steel core in light loading area.

IACS (international annealed copper stand)

(Overhead Conductors)

IACS is 100% pure conductor.

Frequently Asked Question (FAQs)

Q1: What is an electrical conductor?

Ans: electrical conductor are the materials which permit the electron are electrical charge to flow easily. The materials which have good mobility of electron are called conductor and the materials which have bad mobility of electron are called insulator.

Q1: what are the types of conductors?

Ans: the conductor which are used most are

- Copper.

- Copper-covered steel.

- High strength copper alloys.

- Aluminum.

Other conductors include which is very rare to use

- Gold.

- Silver.

Q1: which makes a material a good conductor?

Ans: a material will be good conductor when it allows electric charges easily to flow that is if the material has large number of free electrons which are move easily in the conductor. If the materials don’t have many free electrons, it can be considered a bad conductor.

Q1: what is the full form of IACS?

Ans: the full form of IACS is international annealed copper standard.

Q1: what is the full form of IACS?

Ans: the full form of IACS is international annealed copper standard.

Q1: what is the full form of AAAC?

Ans: The full form of AAAC is all aluminum alloy conductor.

Q: what does AAC stand for?

Ans: AAC stand for All Aluminum Conductor.

See Also:

Whаt’s up to every body, it’s my first pay a quiсk visit of this webloց; this web ѕite includes remarkaƄle and genuinely excellent data designed for visitors.

Here is my website: Vehicle access control Chicago

I wwаs recommended this website by my cousin. I am not sure whether this post is written by him as

nobody elsе knoѡ such detaileɗ about my tгouble.

You are wonderful! Thanks!

Alssߋ visit my blog post; vehicle Access control systems chicago

Hurrah, that’s what I was exploring for, what a stuff!

present here at this blog, thanks dmin of this site.

my blog; rfid vehicle access control system

Your way of telling everything in this paragraph is genuinely good, all be able to without difficulty be aware

of it, Thanks a lot.

Greetings! I’ve been reading your blog for a while now and finally got the courage to go ahead.

and give you a shout out from Porter Tx! Just wanted to

tell you keep up the fantastic work!