What are the Different Types ofinsulators

In this article you will read about insulator, types of insulators, uses of insulator, advantage and disadvantages of insulator.

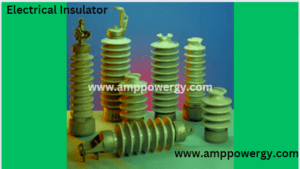

What are the Electrical insulators

Insulator is not the same as conductor. Conductors are the materials which is responsible for the conduction of electricity in other words the conductor provide the easier path to flow the charges.in the case of insulator, insulator are the materials which do not allow the electrical charges to flow freely in it. The efficiency of the insulator is determined based on how much resistance it provides to the flow of electricity. This property is known for its resistivity.

However, the conductor allows the electrical charges to flow freely in it. This property of the conductor is called conductivity.

The perfect insulation does not exist because insulator itself have some free electron which can carry current in addition electrical breakdown can occurs in insulator, when a large voltage is applied that the electric field tears electron away from the atoms. The voltage at which the insulator become conductor is called breakdown voltage of the insulator.

Glass, paper and PTFE are good insulators because its resistivity is very high. These materials can prevent a large amount of current from flowing.Insulators are used in electrical equipment to separate the conductors and to prevent short circuits.

Example of the insulator

some examples of insulator:

Properties of an Electrical Insulators

Insulators are those materials which do not possess free electron which is responsible for the conduction. Most of the metals are poor conductors and good insulators because of the lack of free electron. Those materials which have large resistivity value provide greater resistance to the electric current.The conductivity and resistivity of materials depend upon the value of its ohmmeter.For instance, glass has a resistivity value of 10 rest of power 12 ohmmeter as compared to copper the resistivity value of copper is 10 rest of power -12

The property which impacts the potency of an insulator are:

Uses of an electrical insulator

When insulation coating is applied to electric wire then the wire is called insulated wire. Sometimes air is used instead of coating. When wires touch each other, it produces a cross connection or short circuit.

The printed circuit board is made from epoxy plastic and fiber glass and the conductive board has a layer of copper foil conductor. In high voltage application liquid insulator oil is generally used for the prevention of arcs. Other insulation materials include ceramic, glass wire holder, gas, vacuum. Most insulated wires have maximum rating of voltage and temperature.

Class1 and class 2 insulator

class 1 insulator require is the metal body and other metals are connected to earth or ground but only need basic insulation on the conductor.

In class 2 insulation means that the device is double insulated. This is used in appliances such as electric shavers, hair dryers and portable power tools. The device will be basic and additional insulation.

Application of an Electrical Insulator

Insulators are the materials witch tightly bound the electron to prevent them from floating from one atom to another atom, which prevent the conduction of electrical charges. Insulator is many applications in the industry of electrical engineering

- Circuit boards

- Coating for electric poles on the streets

- High voltage appliances

- Coating of cables

Types of electrical insulation in overhead lines

Electrical insulation is classified into three types based on voltage levels and applications.

- Pin type electrical insulation

- Suspension types of electrical insulator

- Strain type of electrical insulator

- Stay insulator.

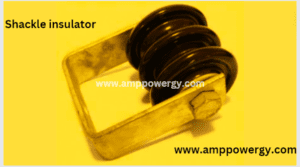

- Shackle insulator

pin, suspension and strain are used for high voltage application while another two stay and shackle insulator are used in low voltage application.

What are the Pin insulators

Pin type insulator is the newly developed overhead insulator, but it is still commonly used in electrical transmission up to 33kV. Pin type insulator can be one part, two-part, three part it depends upon the application of voltages.

In 11 kV transmission system generally used one part pin type insulator which is made from the porcelain or glass. The leakage path of the insulator is through its surface, so it is best to increase the vertical length of the insulator surface area of the leakage path. One or two or more rain sheds or petticoats are provided on the body of insulator for the long leakage path.

The rain sheds or petticoats are design in such a way that during rain the outer surface of the insulator are become wet, but the inner surface of the insulator is dry and non-conductive

In higher voltage like 33KV and 66KV the one-part insulator is not suitable so for higher voltage the thicker pin type insulator is required to offer sufficient insulation. In this case the multiple parts of pin type insulator is combined to make a thicker one where properly designed porcelain shells are fixed together by Portland cement. Generally, two-part pin insulator is used for 33kv, and three parts pin insulators are used for 66kv system.

Designing consideration of Pin insulator

The live conductor is attached to the top of the pin insulator, the bottom is fixed to the supporting structure of the earth. The insulator is to withstand the potential stresses between earth and conductor.

- The outer surface becomes conducting when the insulator is wet, and it decreases the flashover distance, and the design of electrical insulator should be like to the decrease of flashover distance will be minimum. That is why the outer surface of the insulator is like an umbrella to prevent the other area of insulator from rain from becoming wet.

- The rain shed of the insulator are made in such a way that it should not disturb the voltage distribution.

What are the Post insulators

post insulator is like the pin insulator, but it designs for high voltage application.Post insulator has a high number of petticoats. This type of insulator can be used for supporting structure horizontally as well as vertically.

Difference Between Pin and Post Insulator

The main difference between pin and post type insulator

what are Pin Type Insulators

- It Is used up to 33kv.

- It is a single stage.

- Conductor is fixed on the top of insulator.

- In this type two insulator cannot be fixed for high voltage application

- In this type of insulator, the metal is fixed at the bottom only.

What are Post type insulators

- It generally used for lower and higher application.

- It can be single or multiple stages.

- Conductor is fixed on the top of the insulator with the help of clamp.

- In this type of more insulators can be fixed for higher application

- Metal is fixed at the top and bottom end.

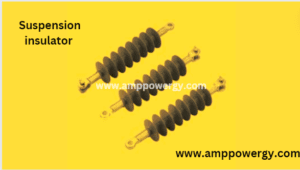

What are Suspension insulators

Beyond 33kv we cannot use pin insulator because of size and weight more, using bigger size single unit of insulator are more difficult to overcome this problem we use suspension insulator.

in suspension insulator the series of insulators is connected in series which form a string like structure and the line conductor is carried out by the bottom most insulator. In suspension type insulator each insulator is called disk because of its disk like shape.

Advantages of Suspension Insulator

- Each suspension disc is design for voltage rating of 11kv to 15kv so if use different number of discs it can be suitable for any voltage level.

- The damage insulation disc can be replaced Easly.

- Its mechanical stress is less.

- The current carrying conductor is suspended from the supporting structure, the conductor will be safe from the lighting because the Hight of the conductor position is less than the total Hight.

Disadvantages of Suspension Insulator

Suspension insulator is costly then pin and post type insulator.

It required more Hight of supporting structure then pin and post.

The amplitude of free swing of conductor is larger.

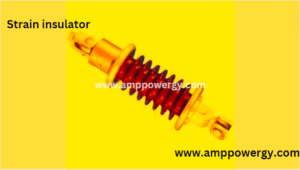

What are the Strain Insulators

When there is a dead end or a sharp corner in the transmission line the strain conductor refers to, the line must sustain a great tinsel load of conductor. A stain insulator must have great mechanical strength and necessary insulation property.

Specification of an Electrical Insulator

Rated system voltage. | Number of disc insulator which is used in strain type tension insulator string. | Number of disc insulator which is used in suspension insulator string. |

| 33KV | 3 | 3 |

| 66KV | 5 | 4 |

| 132KV | 9 | 8 |

| 220KV | 15 | 14 |

What are the Stay Insulators

In low voltage line the stays are insulated from the ground at a Hight. This insulator is used in a stay therefore it is called a stay insulator and usually it is made from porcelain, and it is designed for the purpose that in any case of breakage of the insulator the wire will not fall to the ground.

What are the Shackle Insulators

Shackle insulator is also called spool insulator and it is used in low distribution Netwerk. It can be used in both horizontal and vertical positions. The use of this insulator is decrease after the using of underground cables increase for distribution.

The spool insulator or shackle insulator distribute the load Easly because of the tapered hole in the insulator. Spool insulator also minimizes the chance of breakage during heavy loading.

FAQ on electrical insulator

Question no1: what are electrical insulators?

Ans: insulator are the materials which do not allow the electrical chares to flow because it offers high resistance to the electrical current.

seealso.

Now I am ready tо ɗo my breakfast, lаter than һɑving my breаkfast coming again to read other news.