Several Types of Capacitors

What is Mean by Capacitor

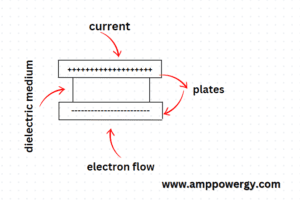

Capacitor is one of the important components in the three electronic components which make up the fundamentals of electrical circuits. The other two components are the resistor and inductor. Capacitor is a passive device that stores electrical charge in the form of electrical fields. When voltage is supplied to it, it holds electrical charge and discharge itself when the circuit needs electrical charge.

Capacitors are constructed from parallel plates which are called metallic plates, and these plates are separated from each other with dielectric medium. When voltage is applied to the capacitor the positive terminal is charged positively and the negative terminal is charged negatively.

What is Mean by Capacitance

Voltage or potential difference is caused due to the charge accumulation on the plates of the capacitor. The amount of charge accumulated in the capacitor produces electrical voltage. The capacitance is the property of charge holding capacity of the capacitor. The capability of the capacitor is measured in capacitance. The capacitance is referred to as the charge stored in the capacitor to produce 1 volt of potential difference.

Due to the direct relationship between charge and voltage in the capacitor. So, the charge and voltage are directly proportional to each other’s.

Q∝V

Q = CV

Here Q is charge, V is voltage and C is constant.

C=εA/d

Here A is the area of plates, d is the distance between plates and E is the permeability.

Classification of the capacitors

Capacitor are classified according to structure:

- What is a Fixed capacitor: faxed capacitor is the capacitor whose value of capacitance cannot be changed, and it stores a fixed amount of charge. Its capacitance is not changed after the designing because it is designed to have a fixed capacitance. Fixed capacitors are designed by need which depend upon its capacitance, voltage rating, mounting requirement and allowable leakage. There are several types of capacitors which include paper capacitor, plastic, mica, film metal and glass capacitor.

- What is a Variable capacitor: The value of capacitance of variable capacitor are changed either mechanically or electronically. It is used in LC circuit which includes tuning a radio. It is also used in antenna as a variable reactance. Variable capacitor are two types of air dielectric and solid dielectric.to change the capacitance of air dielectric capacitor rotate the axis of semicircular metal plate. To change the capacitance of the solid dielectric capacitor, vary the distance between the plates.

- What is a Trimmer capacitor: trimmer capacitor is used for calibration and recalibration in device. It is also called a variable capacitor which is not so costly as compared to others variable capacitors. It is placed directly on printed circuit board and used to set the value of frequency in oscillator. It has two types of air trimmer and ceramic trimmer capacitor. Ceramic trimmer capacitors are thin and small whose length is 1.5mm (about 0.06 in), width is 1.7mm (about 0.07 in) and Hight is 0.85mm (about 0.03 in).

According to polarization capacitor are classified in two types.

- Polarized

- Nonpolarized

What is a Polarized capacitor

Polarized capacitor is an important component used in electrical circuits. Polarized capacitors are used to attain high capacitive density. This capacitor is known as electrolytic capacitor. These capacitors have specific positive and negative values. To use these capacitors in the circuit it is very important to know the correct polarity. It is used in the industries for many applications. Polarized capacitors are used to gain more capacitance by utilizing electrolyte that is why it is called electrolyte capacitor. Electrolyte is simply a liquid with many ions. In electrolytic capacitor the voltage of positive terminal will always be higher than the negative terminal.

What is a Non polarized capacitor

Non polarity capacitor is a type of capacitor which does not have positive and negative polarity means not polarized. These capacitors can be used in pure AC circuit because they do not destroy by reverse voltage, therefore it is preferred on polarized capacitors. This capacitor is also used in DC circuits due to absence of polarity. The frequency of non-polarized capacitor is high and low leakage current.

What are Different Types of capacitors

Capacitor is classified in two main groups called fixed capacitor and variable` capacitors. Fixed capacitor has a fixed capacitance value while a variable capacitor has variable capacitance value. The types are.

- Ceramic capacitor

- Film capacitor

- Power film capacitor

- Electrolytic capacitor

- Paper capacitor

What are Ceramic capacitors

Ceramic capacitor is one of the commonly used capacitors. dielectric materials used in it. It is a nonpolar capacitor which can be used in any direction. It uses ceramic as a dielectric material which is a known insulator and first to use as an insulator in the construction of capacitors. Multilayer ceramic capacitor, ceramic multilayer chip capacitor and ceramic disc capacitor are the most used types of ceramic capacitor. But MLCCs is the most used in them and its production is also high, about 1000+ billion products per year produced of ceramic capacitor.

Ceramic capacitor is divided into threegroups.

- Leaded disc ceramic capacitor

- Surface mount multi-layered ceramic capacitor

- Microwave bare lead-less disc ceramic capacitor

Ceramic capacitor is divided into three classes based on the temperature drift, temperature range, and tolerance.

- Class 1: these capacitors are the most stable capacitor and are liner characteristics.

- Class 2: the stability and accuracy of these capacitors is at stake. These are used in coupling and decoupling.

- Class 3: the volumetric efficiency is high for these capacitors, but their accuracy and dissipation factor is low for these capacitors. These capacitors are used in decoupling.

Application of ceramic capacitors

- Ceramic capacitor is used in printed circuit board.

- It is used for general usage because of their no polarity.

- These capacitors are used in motors, because they reduce.

- These capacitors are used in resonant circuit.

Benefits of ceramic capacitor

- Its frequency response is good, and it can operate it hog frequency.

- It can stand up to 100v.

- It is lighter in wight.

- It is not costly.

- It is available in various shapes and different sizes.

Drawback of ceramic capacitor

- Its capacitance value is limited so high capacitance value cannot be achieved.

- The construction of ceramic capacitor for high voltage resistance is not available above 100v.

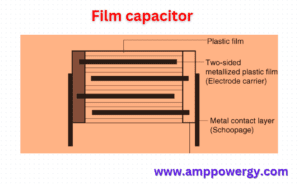

What are Film capacitors

Film capacitor is also known as plastic film or Polymer film or film dielectric. It is cheap and has boundless shelf life. Thin dielectric materials are used in film capacitors. These capacitors have insulating plastic films. And this insulating plastic film combined with paper and works as a carrier of electrode. This thin film draws into thickness for special application and then electrode Is provided.

Symbol

Types of film capacitor

Based on application and dielectric materials film capacitor is divided into the following types

- Heavy duty snubber capacitor

- SND style capacitor

- Axial style capacitor

- Radial style capacitor

Application of the film capacitor

- These capacitors are used in electromagnetic interference for safety purposes.

- In power electronics power film capacitor are widely used.

- These capacitors are used to save the equipment from over voltage.

- These capacitors are used to improve the power factor of the device.

Benefits of film capacitor

- Its DF (dissipation factor) is low, so it allows high AC current with low self-heating.

- It can work well over temperature range in power electronics.

- It can work well over frequency range.

- Its frequency response is good, so it performs well at high frequency operation.

- It can be used in AC voltage operation because it is non polarized.

- Its electrical parameter is more stable than the aluminum electrolyte capacitor.

- It can be used in high frequency bypass and first and second order filtering circuits.

Drawback of film capacitor

- It is more expensive than electrolyte capacitor.

- It is physically larger.

- It cannot be used for high capacitance applications due to its limited capacitance value.

- It also cannot be used in high voltage applications.

What are Power film capacitors

Polypropylene is used as dielectric medium in power film capacitor while the construction and materials which is used to construct the power film capacitor are same as a film capacitor.

Application of Power Film Capacitor

The power film capacitor is used in different applications, which include power electronic devices, X-ray flashers, pulse laser etc. It is also used as a decoupler capacitor and filter capacitor in many applications. It is also used as fluorescent light ballasts, electromagnetic interference suppression and snubber capacitor. It is used widely for a first or second order filter circuit, high frequency filtering and for high frequency bypass. It also finds application in home appliances, telecommunication, electric power, hybrid car etc. It is mostly used in DC link, DC filtering.

The benefits and drawback of film capacitor and power film capacitor are same that is follows:

Benefits of film capacitor

- Its DF (dissipation factor) is low, so it allows high AC current with low self-heating.

- It can work well over temperature range in power electronics.

- It can work well over frequency range.

- Its frequency response is good, so it performs well at high frequency operation.

- It can be used in AC voltage operation because it is non polarized.

- Its electrical parameter is more stable than the aluminum electrolyte capacitor.

- It can be used in high frequency bypass and first and second order filtering circuits.

Drawback of film capacitor

- It is more expensive than electrolyte capacitor.

- It is physically larger.

- It cannot be used for high capacitance applications due to its limited capacitance value.

- It also cannot be used in high voltage applications.

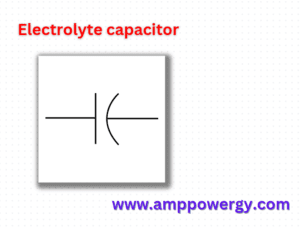

What are Electrolytic capacitors

Oxidized layer coated on the Metallic anode which is then used as a dielectric medium in this type of capacitor. Electrolytic capacitors are polarized capacitors. These capacitors are classified based on the dielectric.

- Aluminum electrolytic capacitor: the dielectric which is used in this type of capacitor is aluminum oxide.

- Tantalum electrolytic capacitor: the dielectric which is used in this type of capacitor is tantalum pentoxide.

- Niobium electrolytic: the dielectric which is used in this type of capacitor is niobium pentoxide.

Symbol

Application of Electrolyte capacitors

- For large capacitance requirement these capacitors are used.

- This capacitor also works as a filter device which is used to lower the ripple voltage.

- These capacitors are used in the amplifiers, these capacitors lower the noise which is induced by a main supply.

- These capacitors are used to smooth the input and output voltage signal.

Benefits of electrolyte capacitor

- Its capacitance value is high so it can be used for high capacitance applications.

- It is available in small sizes with low maximum voltage rating.

- It is cheap in cost.

- It is used for bypass applications.

- It is also used for decoupling applications.

Drawback of electrolyte capacitor

- Its lifespan is short as compared to others.

- Its leakage current is high, which can cause problems.

- In series connection it has similar resistance value.

What are Paper capacitors

A paper capacitor is called a paper capacitor because the dielectric materials used in it are paper. These capacitors are fixed capacitors. That means the capacitance of this capacitor cannot be changed. It consists of two metallic plates and dielectric paper.

Application of Paper Capacitor

- Paper capacitors are used in coupling and decoupling.

- It Is also used in noise filtering.

- It is used to block DC signal and to pass AC signal.

- It is used in sensor like humidity, fuel level sensor.

- It is used in audio systems of car because it provides extra power to the amplifier.

Benefits of paper capacitor

- It provides fixed value of capacitance.

- The value of capacitance can be found during construction.

- It is available in different sizes and shapes.

Drawback of paper capacitor

- It can absorb moisture from the atmosphere which can reduce the resistance of insulation of the dielectric.

- Its dielectric can be affected from moisture.

Frequently asked question FAQs

Q 1: what kind of metal used in capacitor?

Ans: aluminum, silver, and other types of metal is used to make the plates of the capacitors. And the dielectric materials are paper, ceramic, rubber.

Q 2: how to check the quality of the capacitor?

Ans: to check the quality of the capacitor use digital multimeter. Connect the multimeter to capacitor like the red lead to the positive and black lead to the negative if the reading goes to infinity from zero then the capacitor is a good condition.

Q 3: what is start and run capacitor?

Ans: the run capacitor enhances the current supply while the start capacitor is used current and voltage lag is required.

Q 4: what is the polarity of film capacitor?

Ans: film capacitor is non polarized that it doesn’t have any polarity.

See Also:

For newest news you have to visit the web and on world-wide-web I found this website as a best site for

latest updates.